Maximize Your Processes with a Trusted Partner

For over 25 years, AutomaTech has been helping manufacturers optimize their critical processes and preserve asset investments by improving equipment capacity. Our solutions help maintain product quality while reducing changeover time and runoff because of market demands for shorter runs.

Benefits of Choosing to Partner With AutomaTech

AutomaTech stands behind our solutions, helping you maximize your investment.

Consistency

Reduce Costs

Improved Quality

Time to Value

Collaborate with AutomaTech to learn ways to improve operational efficiencies, compress time to market by leveraging innovation.

For OEMs & Equipment Suppliers

OEM Decisions

Build

Buy

Featured Examples

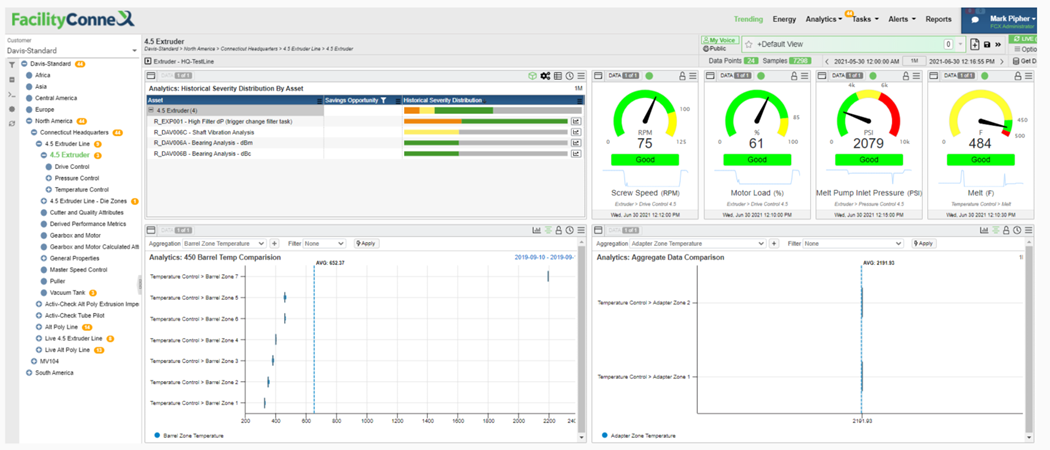

Why they selected OEMConneX?

- Proactive analytics and notifications for quicker time resolution

- Monitoring and alarming without on-premises servers.

- Abilities to understand high reliability data collection and recovery needs for their user base

- Browser based and native mobile clients

- Email and alarm based SMS alerting

21 CFR part 11 (GxP) Compliance including E-signature

Value Received

- Time to get solution to market

- Highly reliable edge to cloud solution

- Solidified expertise for creating, managing, supporting a cloud based platform with partnership.

Driving Industrial Innovation To Transform Your Business

- Improve Machine Performance & Analytics

- Simplify Secure Remote Machine Connectivity

- Automate Systems, Data Collection, and Reporting

- Drive Additional Value & Revenue Streams

We partner with OEM customers to offer customized training, enabling you to drive business development and generate new revenue streams.

Optimize Your Machine

HMI Innovation and the Next Generation of OEM Equipment

Industrial innovation requires a company that helps resellers and OEMs learn about its technological solutions, enables resellers to bring solutions to their markets, and supports those solutions to delight customers.

Resellers serve as an invaluable bridge between technology innovators and OEMs. Value-added resellers understand both the technology and the industrial market, which helps OEMs implement solutions more quickly and efficiently.

OEMs must transition their many different customer platforms and control systems to Industry 4.0 and meet evolving HMI standards.

HMI innovation provides OEMs with a value added service to offer customers in the future. Long-term data collection in the cloud will provide the monitoring necessary for OEM customers to improve their performance.

Our Customers Say It Best

"We see this as a service option we can provide customers on any system that uses a PLC. As the Industrial Internet of Things grows, this is something that will become standard on all our systems."

- John Clemens, Davis-Standard