New Legislation Makes Cobots an Even Greater Financial Advantage for Manufacturers

On July 4, 2025, new legislation was passed providing manufacturers with expanded financial incentives to accelerate automation adoption. The goal of this bill is clear—to help industrial companies combat persistent labor shortages and rising operational costs. For many, investing in collaborative robots (cobots) is now one of the fastest and most cost-effective ways to reduce expenses and improve return on investment (ROI).

Across nearly every sector, operations leaders and plant managers are asking the same questions:

How can we maintain productivity with fewer skilled workers?

What’s the real cost of turnover on production schedules?

Is automation practical for small to mid-sized manufacturers—or only large enterprises?

This new legislation underscores a key reality: cobots are no longer a future concept—they’re a present-day solution that addresses immediate workforce and production challenges.

Why Cobots Are Becoming Essential in Modern Manufacturing

Labor shortages remain one of the biggest threats to industrial growth. Job openings in manufacturing continue to rise, while qualified labor becomes harder to find. Cobots bridge this gap, performing repetitive, high-volume tasks without breaks, absences, or burnout.

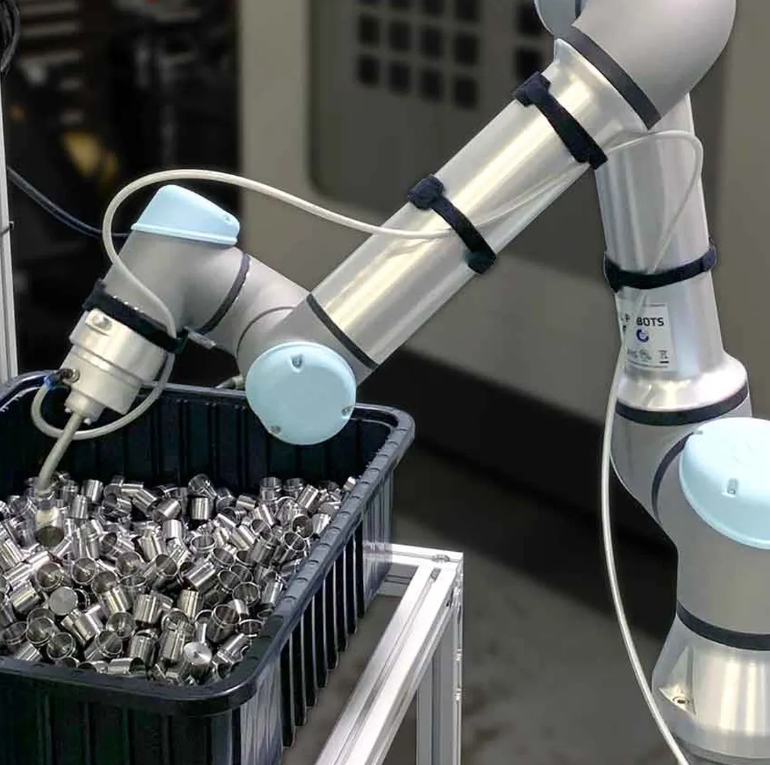

Unlike traditional robots, cobots are specifically engineered for flexibility and ease of use in smaller operations. They’re compact, safe to operate around people, and don’t require expensive guarding or complex programming to get started.

The ROI is both measurable and fast. A typical cobot installation ranges from $35,000–$75,000, yet pays for itself within 6–12 months, often saving $65,000–$75,000 per year in labor-related costs.

Cobots Support Workers—They Don’t Replace Them

A common myth surrounding automation is that it replaces people. In truth, cobots empower workers by taking over the dull, repetitive, or physically demanding jobs that lead to fatigue and injuries. Examples include:

Palletizing and repetitive lifting tasks

Machine tending during overnight or hard-to-staff shifts

Packaging and labeling high-volume products

By offloading these time-consuming duties to cobots, employees can focus on higher-value responsibilities—quality inspection, troubleshooting, process improvement, and innovation. Cobots strengthen the workforce rather than replace it.

What This New Legislation Means for Plant Managers

The message from policymakers is clear: automation is now an accessible advantage, not a luxury. Barriers to entry have dropped dramatically, allowing small and mid-sized manufacturers to compete on efficiency and reliability. Waiting until labor challenges worsen could mean losing ground to competitors who adopt automation early.

Start simple—implement one cobot on one task or shift. Many facilities see measurable results in productivity and uptime within weeks.

Key Takeaway for Manufacturers

If your team is struggling with labor gaps, missed deadlines, or rising overtime, now is the time to evaluate how cobots can enhance your operation. Don’t wait for workforce shortages to slow your production—start exploring cobot solutions today.

With the right strategy, automation can strengthen your team, reduce costs, and help you achieve long-term growth.